What Are Bolts?

Bolts are essential fasteners used to join materials by passing through them and securing with a nut. Unlike screws, bolts typically have a blunt end and require a nut for fastening, making them ideal for heavy-duty applications.

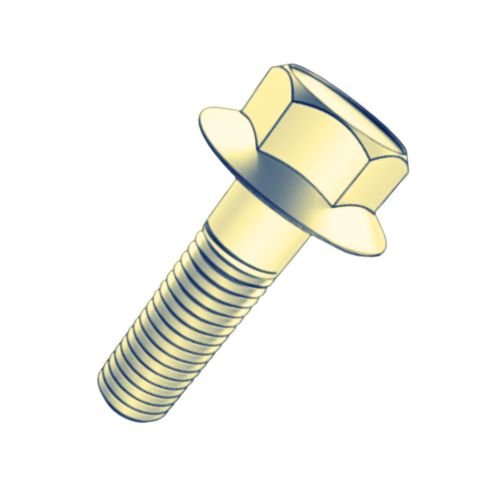

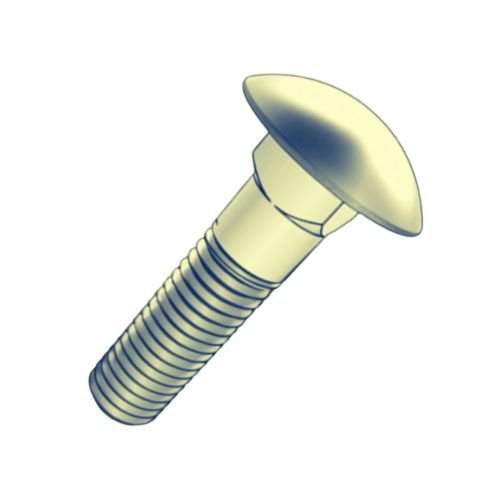

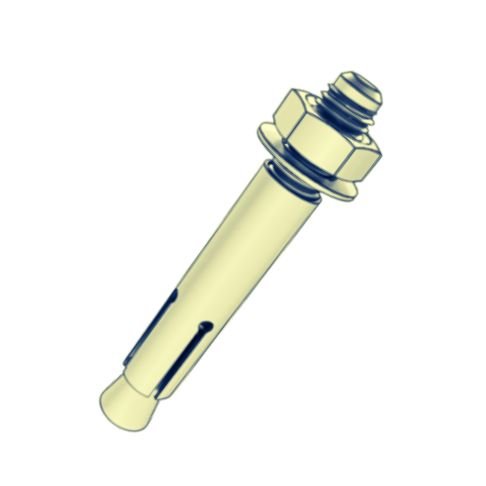

At BaiGu Fastener, we offer a wide range of standard bolts, including hex bolts, carriage bolts, and anchor bolts, as well as custom solutions tailored to your needs.

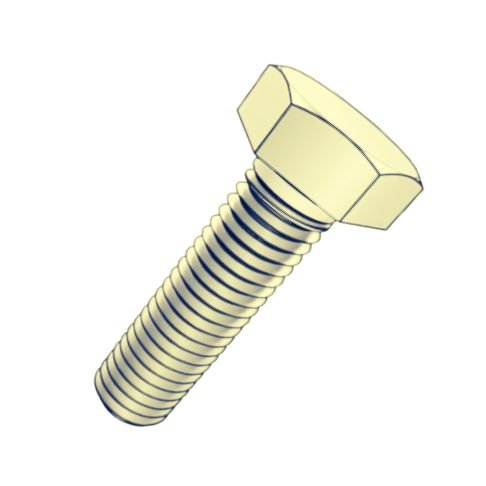

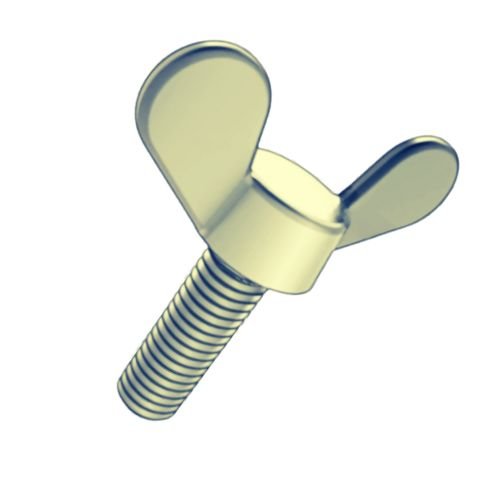

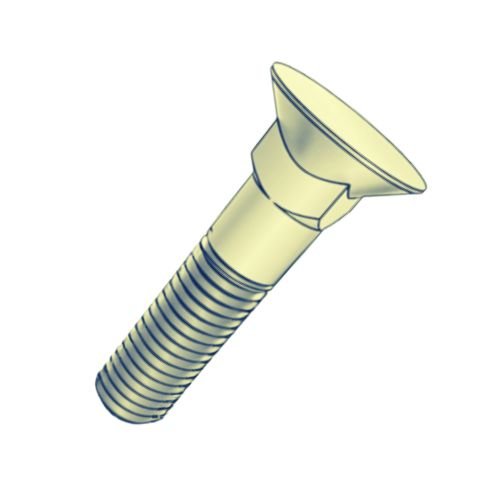

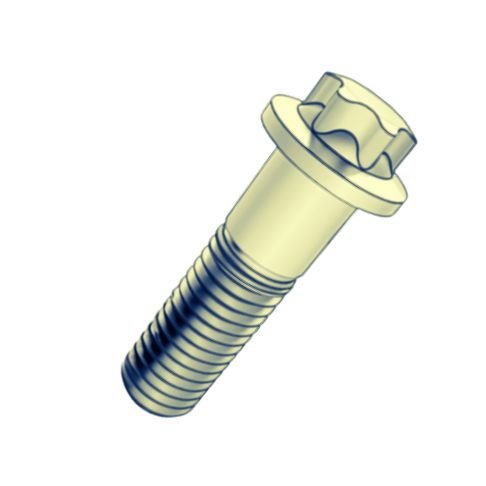

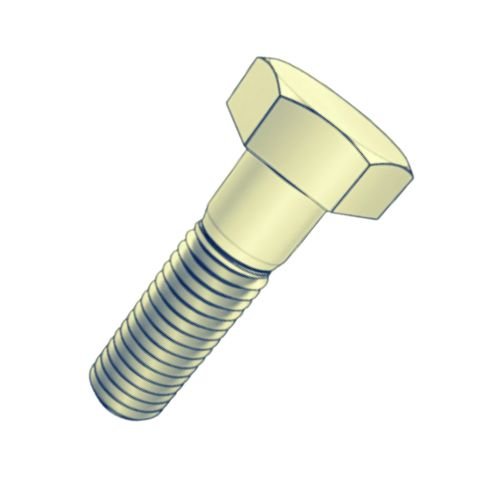

Types of Bolts

Bolts Materials

The choice of material is crucial for bolt performance. Our bolts are available in:

- Steel: High-strength, cost-effective, often coated with zinc for corrosion resistance.

- Stainless Steel: Ideal for outdoor or corrosive environments, offering excellent rust resistance.

- Brass: Used for decorative applications or in low-corrosion settings.

- Aluminum: Lightweight, suitable for aerospace and weight-sensitive projects.

- Titanium: High strength-to-weight ratio, perfect for extreme conditions.

Bolts Finishes

Popular finishes include:

- Black Oxide: Sleek, dark finish for aesthetic and mild corrosion resistance.

- Hot-Dip Galvanized: Thick zinc coating for heavy-duty outdoor use.

- Zinc Plating: Commonly used are blue zinc, white zinc, yellow zinc.

Applications of Bolts

Bolts are versatile fasteners used across multiple industries. Here are key applications:

Construction

Hex and anchor bolts secure steel beams, columns, and foundations in buildings and bridges, meeting ASTM standards for structural integrity.

Automotive

High-strength bolts, like grade 8, are used in engines, chassis, and suspension systems, ensuring safety and durability.

Aerospace

Titanium and stainless steel bolts provide lightweight, high-strength solutions for aircraft and spacecraft.

Manufacturing

Bolts assemble machinery and equipment, offering reliable connections under heavy loads.

DIY Projects

Carriage and lag bolts are popular for home projects like furniture assembly, deck building, and fencing.

Fastener Standards and Specifications

Fasteners are manufactured according to standards that dictate dimensions, tolerances, materials, and mechanical properties. Key standards include:

- ISO (International Organization for Standardization)

- DIN (Deutsches Institut für Normung)

- ANSI/ASME (American National Standards Institute / American Society of Mechanical Engineers)

- JIS (Japanese Industrial Standards)

- BS (British Standards)

Choosing the Right Fastener

Selecting the appropriate fastener depends on several factors:

- Material compatibility

- Load-bearing capacity

- Environmental conditions (e.g., exposure to moisture, chemicals)

- Vibration resistance

- Ease of installation

- Cost-effectiveness

Why Choose Our Standard Fasteners?

At BaiGu Fastener, we pride ourselves on delivering exceptional products and services:

- Quality Assurance: Every fastener undergoes rigorous testing to meet industry standards.

- Competitive Pricing: Affordable solutions without compromising quality.

- Fast Delivery: Bulk orders (e.g., 3 tons of screws, ~0.57 m³ with packaging) shipped efficiently worldwide.

- Expert Support: Our team assists with material selection, customization, and technical queries.

Frequently Asked Questions (FAQs)

How do I choose the right fastener for my project?

Consider the materials being joined, the environment (e.g., indoor vs. outdoor), load requirements, and desired finish. Also, determine if the fastener needs to be removable or permanent.

What is the difference between metric and standard fasteners?

Metric fasteners use millimeters (e.g., M6 for a 6mm diameter), while standard (imperial) fasteners use inches (e.g., 1/4-20 for a 1/4-inch diameter with 20 threads per inch). Metric is common in Europe and Asia, while imperial is prevalent in the U.S.

What are the most common sizes of standard fasteners?

Common sizes include M3, M4, M5, M6, M8, M10 (metric) and 1/4-20, 5/16-18, 3/8-16, 1/2-13 (imperial). These are widely used across industries.

Are standard fasteners suitable for outdoor use?

Yes, if made from corrosion-resistant materials like stainless steel or coated with zinc or galvanization to prevent rust.

What are the advantages of using standard fasteners over custom ones?

Standard fasteners are cheaper, more available, and easier to replace. Custom fasteners are tailored but more expensive and have longer lead times.

How do I prevent fasteners from rusting?

Use corrosion-resistant materials like stainless steel or apply coatings such as zinc plating or galvanization. Keep them dry and clean.

Can standard fasteners be reused?

Yes, if undamaged and properly cleaned. Screws driven into wood may not be reusable due to thread wear.

How do I convert between metric and standard fastener sizes?

Use conversion charts: 1 inch = 25.4 mm, but thread pitch differs (e.g., M6 ≈ 1/4-20).

What are the different thread types for standard fasteners?

Include coarse (easier assembly), fine (better holding power), and metric threads.